No More Flat Tires: Gecko Cellular Rubber Punctureless Tires

By Richard Peace

By Richard Peace

Solid and cellular tyres are one of those bicycle design ideas that potentially hold huge practical advantages; no punctures and none of the extra time and delay that entails and the need to carry round a spare tube, tools and pump with you.

But product launches of solid tyres over the years have come and gone and reviews of them in the cycling press have been almost universally deeply critical.

Attempts were lambasted as extremely harsh to ride and at worst dangerous, with the danger of tyres coming off the rim or skidding on the road surface. At best they were hard to ride with huge rolling resistance and a jarring, uncomfortable ride.

In 2015 South Korean company Tannus launched their ‘solid’ tyre, actually made of foamed polymer which was the first bicycle non-pneumatic tyre to be generally well-received, though difficult to put on and remove the tyres from the rims.

Now Gecko Rubber from the UK has produced their own version of punctureless tyres, made from a cellular rubber compound (based on traditional thermoset rubber compounds similar to those being used in conventional pneumatic tyres). They claim to have a softer ride than Tannus and to be ‘70% less damaging to the environment than a leading puncture resistant alternative.’

I’ve tried both Tannus and Gecko tyres and whilst I haven’t done any scientifically meaningful comparison I can say both worked well, the main difference between them and regular pneumatics being the slightly harsher ride of both non-pneumatic versions. Gecko claim greater vibration damping than Tannus, though as I didn’t have equivalent bikes at the same time kitted out with equivalent size tyres I couldn’t verify this.

Whilst ride quality and rolling resistance of the new punctureless breed of tyres may not be up there with pneumatics they are clearly here to stay and three possible markets stand out to me; short hop round town public hire bikes, short hop ‘hack’ bikes and …..electric bikes.

Any extra rolling resistance will, to a large degree, be cancelled out by the extra motor power and any extra hassle of changing punctures on heavier electric bikes disappears.

Gecko are now looking to roll out their rubber compound from small production runs of 26” sized tyres to longer runs and different sizes and would welcome approaches from both the electric bike community and electric bike manufacturers.

Having ridden a test electric bike equipped with Gecko tyres for several weeks, the problems of old puncture proof tyres are certainly banished; I felt quite happy and safe cornering at speed on all manner of surfaces and, whilst the ride was definitely harsher than equivalent size pneumatics at a medium tyre pressure, it certainly wasn’t so off putting I didn’t want to ride the bike.

Gecko say the tyres have been on extended trial in the UK on public hire bikes and feedback has been of no problems and no negative feedback from the hire scheme users.

Get in touch with Gecko here.

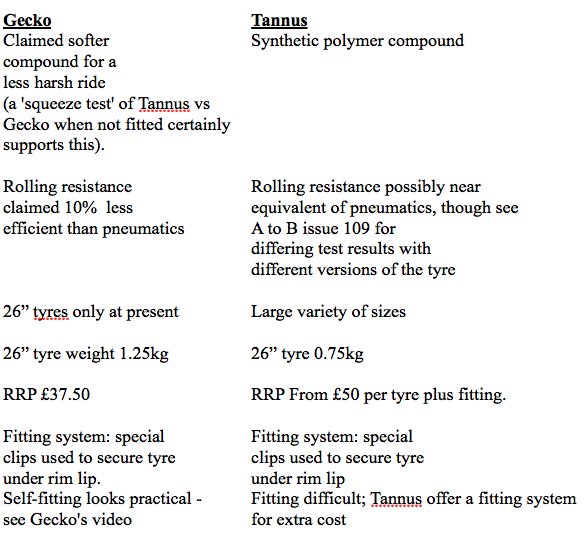

Gecko vs. Tannus

Gecko Mounting clip system

Stay tuned for more eBike component and accessory reviews!

P.S. Don’t forget to join the Electric Bike Report community for updates from the electric bike world, plus ebike riding and maintenance tips!

Reader Interactions

Comments

Trackbacks

-

[…] have tested Gecko ‘solid’ tyres at EBR already, but the company has recently rolled out a new size with a softer compound that gives a more […]

-

[…] has explored the world of cellular punctureless tyres before, but now Gecko have launched a new compound version of their 26″ x 1.75″ tire (for ETRTO 559 x […]

-

[…] If you want to know more about the background to puncture proof tyres see our article on the launch of Geckos here. […]

hello. There is too TANNUS and GREENTYRE.

I did try ‘solid’ tires a few years ago.. for about one day! I concluded that because the energy of ‘pothole’ hits is NOT transmitted around the rim to the entire tire/rim unit, they are extremely dangerous. Eg, a tube-tire , upon impact, will experience massive increase in air pressure involving the entire wheel .. This is not so in any design that restricts ‘pressure/energy’ so it’s localized at the point of impact..

The risk of total wheel failure, in my engineering view, is just tooo great to justify replacing tube or tubeless tires with ‘more solid’ even cellular, designs.

I have used ”No-Mor Flats” and will continue to use them as they work great for me I get thousands of miles out of mine and never any problems, True you have got to use the right size of tire anf Yes you have to totally destroy the old tire to get them off of the rim,say you ”taco’d your Rim in an accident,but Oh Well’ Thats’ life, I have really enjoyed not having any flats……..They work great for me!!

I Love them!!!!