Visit to EcoSpeed Headquarters (Mid Drive Electric Bike Kit)

The Pacific Northwest is a land rich in cycling culture. For many here, bikes are used as the core transportation vehicle year-round and in every type of weather. Portland, Oregon embraces bicycles and electronic bicycles are going ‘on’ in a big way. One company at the heart of the movement is EcoSpeed. The company recently invited me over for a conversation and to go on a ride with some of their machines. EcoSpeed crafts power systems for electronic bicycles. Unique in many ways, EcoSpeed provides a combination of features that will compel many more people to incorporate the electric bicycle into their daily lives.

Brent Bolton is the founder of EcoSpeed. Bolton spent time with Intel and has a background ranging from electronics engineering to race car design. The consensus from those that install and use EcoSpeed in their businesses has been “The EcoSpeed system is assembled so well it’s almost over-built – and we consider that a really good thing.” Certainly, having a system like EcoSpeed available has broadened the scope of what is possible with electric bicycles, today.

EcoSpeed is positioned as a very high quality system and carries it’s price tag accordingly. Systems are priced on their website without batteries and vary from $2,495 – $2,995. Batteries can cost between from $200 to $1300 or more depending on customer needs. All told, one could expect to pay about $4,000 for a complete EcoSpeed system. For the price sensitive, it is possible to source batteries elsewhere, which can help a rider be up and running for under $3,000. With that said, carbon bikes today without electric assist can easily surpass the $10,000 mark. The way we see it, a cargo bike with EcoSpeed for example could carry a large payload, while cruising at speeds rivaling – or eclispsing – a carbon race bike with a world class rider on it. This, while retaining the feel, freedom, and ridability of a bicycle. Yes, the convergence of the bicycle, brushless electric motors, battery technology and bright minds are bringing us bikes that are more useful and fun than ever.

Left to right: EcoSpeed Operations Manager Brad Davis , Founder Brent Bolton, Director of Sales & Marketing Tad Beckwith.

Left to right: EcoSpeed Operations Manager Brad Davis , Founder Brent Bolton, Director of Sales & Marketing Tad Beckwith.

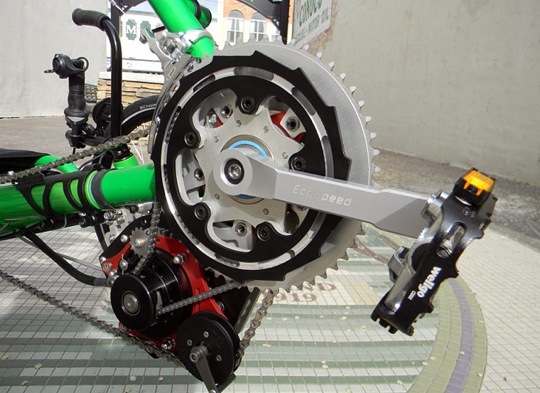

EcoSpeed is a mid-drive solution. Mid-drive motors apply power at the crankset as opposed to motors that are built into hubs at the wheel. There are significant advantages to a mid-drive system. First of all, the entire range of gears on the bike are usable. This is important any time hills and heavier loads are encountered. When speeds slow down, bicycle wheels turn slower. Hub motors are forced to spin at those lower RPM’s, which can quickly burden them. If a strong rider can continue to supply ample wattage to a hub motor under those conditions, they may be able to handle the terrain and load well. If a rider is not generating a lot of power on their own, or is carrying heavier loads, they can shift into a lower gear and the EcoSpeed motor will happily continue to spin in it’s desired range and comfortably keep a good tempo up the climbs. Torque? Not only is the EcoSpeed motor ‘torquey’, but the mid-drive allows for a 5x boost in torque from having all the bikes gears available. There is well over 100 foot pounds of torque being delivered to the drive spindle.

Another advantage of the mid-drive system is weight. The EcoSpeed kit (not including battery) comes in at about nine pounds. An equivalently powered direct drive hub motor can fall in the 16-22 pound range. When power is not being applied, some hub motors (direct drive) still have drag at the wheel. EcoSpeed does not apply drag at the wheel when power is not used. With two freewheels in the system there is no regenerative braking with an EcoSpeed mid-drive. EcoSpeed’s analysis has shown re-charging and braking functions of electric bicycle motors to be of minimal value in real world application.

Mid-drive systems like EcoSpeed do bring with them other inherent issues. Installation is more complex than a hub motor. If you have a shop like Splendid Cycles in Portland that specializes in systems like this, allowing them to do the work may be a good idea. Further, EcoSpeed puts out from 750-1300 watts. While the system itself is very robust, the drivetrain components that it transfers power to are not always up to the task. Of course, there are always variables and how the system is used ultimately determines product life cycles. There have been reports of Shimano Nexus hubs crying ‘uncle’ under the combo of mileage, heavy hauling, and EcoSpeed. Exactly how long and under what type of stress such breakdowns may occur, we don’t have good information on what one could expect.

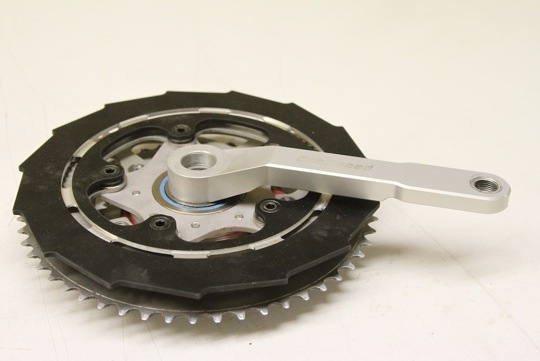

There is a high-quality White Industries freewheel body built into the crankset. Why is there a freewheel body in the crank? This is what allows crank-driven power to be applied to whatever gearing system the bicycle uses at the rear wheel. Whether the rider is pedaling or not, power can come from the EcoSpeed motor with a little move of the rider’s thumb.

Here the smaller-toothed fourth chainring is visible just right of the thick, black chainring guard.

EcoSpeed uses the same motor across all bicycle platforms. Encased in an extremely durable housing that is finned for heat dissipation, the motor generates 1,300 watts. 1,300 watts is a substantial amount of power. In human terms, that is a figure generated by a strong bicycle racer in an all-out sprint for the finish. Having such a boost available with the push of your thumb, whether you are pedaling or not, is thrilling. More important, it is extremely useful.

Now that’s a chainring. This image shows the system on a recumbent trike. Note the small drive chain that runs from the gear on the motor around the crankset.

Another unique feature of the EcoSpeed system is the controller box. Dubbed Velociraptor, the controller box allows EcoSpeed to program systems with software that helps performance in any given application. Because one motor is used throughout all platforms, Velociraptor allows for more ideal functionality on each different bike. The controller also monitors the motor and battery for reliability and safety.

Controller box visible next to EcoSpeed motor on recumbent.

The controller box has a switch available for two different watt output settings. Standard kits can toggle between 750 and 1300 watts.

The standard EcoSpeed battery is a 48 volt, 12 amp-hour lithium tri-metal unit. EcoSpeed partnered with US battery maker AllCell to make certain the system delivers not only high power, but consistent reliability, lower weight, and maximum energy density. Making the switch to newer tri-metal (LiNiMnCoO2) technology allowed EcoSpeed to cut battery weight in half. Component quality throughout the entire EcoSpeed system is exceptional. The battery has a locking u-bolt to give owneres the ability to lock the unit directly to the bike. Battery weight is about 11 pounds.

The 48 volt, 12 amp hour tri-metal (LiNiMnCoO2) battery is housed in it’s own protective aluminum box and Cordura cover. System on/off switch is visible to the right. This unit is plugged directly into a regular wall outlet and full charge is reached in about five hours. In standard configuration on a single bike (one battery, one rider, two wheels), range will be 30-40 miles on a single charge. Remember, that is always a subjective figure of sorts. When and how to use what’s in the battery is part of the enjoyment of riding. Used more sparingly, it could be spent over a much longer distance.

EcoSpeed system installed on one of the B-Line PDX delivery trikes. One of the most industrial bikes on the planet, this trike sees service daily, delivering payloads of 600lbs. That is in addition to the weight of rider and trike. Total weights en-route are often in the 1,000lb range, and the EcoSpeed system helps them move along in the 11-13mph range.

This thumb lever is where the magic happens. The lever must be held in place to add power. It’s easy to hold at every level and even low to mid-range boost is very usable. As soon as the lever is released, power from the motor ceases.

Dashboard on a daily-driver recumbent. Cycle Analyst digital readout is visible at center of stem, low in the image. It measures instantaneous, volts, amps, watts, accumulated amp-hours, and tracks battery charge-discharge cycles. Thumb power control visible by left grip. Riding this bike on a cold day with some rain, I was happy to have the fairing. Easily cruising at speeds of 20-30mph I noticed it was significantly warmer with the fairing.

Splendid Cycles in Portland sells cargo bikes with EcoSpeed fitted and uses the system on it’s own shop bikes made on the Bullit frame out of Denmark. This is yet another great application of the product. These bikes are capable of sustaining speeds over 30 mph (bike in foreground would be more limited by the size of gearing in the internal rear hub), with load, given a pilot that can add significant wattage. Perhaps best of all, it will also claw it’s way up the steepest slopes at a decent pace – even with a trailer added. Splendid Cycles has created some very seductive additions to cargo bikes. One addition is a battery tray under the cargo box that conceals the battery and can hold about all the battery power one could possibly use.

EcoSpeed installed on a very pretty Metrofiets cargo bike.

With a small front wheel, relatively small dog, and a small electric motor here, some might think there isn’t much power in this picture. They would be oh so wrong.

The everyday bike of EcoSpeed’s Tad Beckwith. This suspended Bike-E is fast, comfortable and useful. It uses a NuVinci drive. I could have used a bigger gear on the NuVinci when this bike was in full EcoSpeed stride.

Many different type bikes were ridden during my visit. I was struck by broad range of use of the EcoSpeed system. There is something here for nearly everyone. EcoSpeed has made it their philosophy to maintain the feeling of the bicycle, without trying to turn a bicycle into a motorcycle. They have done exactly that. Their level of build quality that is exceptional. This is a system that is worthy of fitting on the finest made and most beautiful bicycles, as well as the hardest working industrial applications. On cargo bikes, upright singles, tandems, recumbents, industrial trikes, pedicabs, and velomobiles, EcoSpeed delivers it’s performance with quality, usability, and longevity.

P.S. Don’t forget to join the Electric Bike Report community for updates from the electric bike world, plus ebike riding and maintenance tips!

Reader Interactions

Comments

Trackbacks

-

[…] if you have the $$ then this is one of the better assist kits available in the US. Visit to EcoSpeed Headquarters (Mid Drive Electric Bike Kit) The added efficiency of running through the same gears as the HP portion of the powertrain means […]

-

[…] EBR correspondent, Paul Willerton, recently visited the EcoSpeed headquarters (mid drive electric bike kit company in Portland Oregon) and provided this report with lots of pictures! […]

-

[…] is an article about a visit to the EcoSpeed headquarters in Portland, […]

Dear Pete,

Great story on EcoSpeed. I’ve had mine now for over four years and I LOVE IT! It takes me everywhere I want to go and then some. Mines on a sun trike and has a special reinforced basket so I can carry my chicken feed or three large bags of groceries. I use it as my transportation around town and always get great comments about my ride. I take all of my packages to the post office on it for Mama Jean’s. I wish more people could test ride one, then they would understand there really is a new way to get around. The support that EcoSpeed also can’t be beat. All in all, I just can’t say enough about how incredible I think the system is and how it rocks my world.

Hi Mama Jean,

Thanks for sharing your story! Yes, e-trikes are great car alternatives. Enjoy the ride!

Pete

hi..

i’ve been using ECOSPEED mid-drive system for a couple months now and there are few things to note.

1. batteries, i have never tried their batteries because i was and still persistent that batteries should not be mounted on rack because: a. it takes up valuable carrying space, and b. it alters the handling of your bike, balance wise and mounting and dis-mounting, this is true for e-bike kit not just ecospeed. this is why i always try to put my batteries in the triangle portion of the frame, which is valuable real-estate. BUT, in any case you want to custom order battery from somewhere else be sure to run it’s specs, (battery cells, and BMS) with ecospeed to make sure it’s up to their performance requirements which are high. this is why pingbattery has line of batteries specially suited for ecospeed, also be careful from shady alibaba suppliers of batteries, anyway, when you do get a battery, it’s a good i idea to have TWO chargers, one of the home, another for the rode. just in case.

2. chainring -. since the whole setup revolves around gears it would makes sense (to me at least) to have more of them to be more efficient, however if you go for the single chainring setup as i did (cause i never really used the smallest and highest) do NOT try to run with the first and second gears (the one you use for climbs etc) , this is because in this mode the chain is “cross linked” (a term also coined for regular bikes riders that indicates extreme wear to the chain). however when ecospeed motor comes to play, the amount of force applied heavily on the chain ring. usually that won’t matter unless you run in first/second gear, in that angle the chain will being pull and bend the teeth of the chainring back, until you’ll eventually begin to have chain drops, as the chain starts to miss the bent teeth,

3. gears – it was mentioned that nuvinci is being used with some of the bikes, although it’s considered very durable strong, nuvinci themselves specially state that using their hub hears with any motor stronger then 250 watts will void the warranty as well as shorten the riding distance from 25000 to 6000 miles. with that said i myself am using shimano’s alfine 11, because it’s only hub gear that uses thumb shifters.

4.chain – the more gears you’ll have the thinner the chain gets. and thinner chains brake more easily, since ecospeed really runs them down make sure to ride with strong good quality chains, i’ve heard srams are better then shimano’s in this regard.

5. rear wheel – although not a hub wheel setup, the added weight (especially if it’s on the rear rack) can cause the wheel to become untrue (bent), faster then normal rides, especially if you like to jump of sideswalks to the road, once again, make sure to order good quality crazy strong hub (like rigida) and extra thick double butted spokes, this will usually require you to have it custom built but it’s worth it, there are some online stores which custom build them .

6. head lights – although lights seem like a small issue compared to the previous ones, the speed in which you’ll travel makes them very essential to you health and safety, as your response time will be shorten dramatically, especially if you ride on a dark trail with bad street lights, then it becomes to get scary. but having lights means you have to take care replacing their batteries, which becomes a hassle. UNLESS you use lights which can be plugged in to your main battery, this way can rest assure they won’t be shut down in the middle of the ride (unless you run out of battery off course, see item 1). such lights can be ordered with ebikes.ca (the makers of cycle analsyt ).

7. monitoring – speaking of cycle analsyt, there’s another device which allows you to plug you ebike into a smartphone, which can have many additional features (like text to speech report so that you won’t be forced to look at the display as you hurl 20-30 mph), as well locking your e-bike. it’s called speedict.

8. throttles – this is a sore subject with every e-bike. it’s hard to find something is comfortable. but when it comes to mid-drives it’s even more problematic if you intend to use shifting all the time, don’t forget that most of the time your grip will be different then with a normal ride when you twitch/twist the thumb/twist throttle, what’s worse is that the throttle is right handed (99% of them are right handed), the same side as the shifter, and from unexplained reason all of them are built in a way that makes them very hard to place them next to the shifter, there are very few left handed throttles, or ones that can be used by a left hand side. so you night need to do some testing here. so the combination of throttle +shifter AND brakes, becomes something of a trial and error, but very important none the less.

Thanks for all the detailed info Elhanan! Have you been able to shift under load with the Shimano Alfine 11 speed internally geared rear hub?

When you say load you mean motor load? As it won’t be wise.

Yes, and thanks for letting us know.